Making sure that CertiFiber Pro® Output Ports are clean

With fiber optics testing, we all understand the need for cleanliness; dirty fiber connectors can lead to poor network performance and can lead to false failures during certification testing.

Many technicians and engineers performing fiber optic installation work understand that it is important to inspect and clean if necessary the Test Reference Cords (TRCs) that are used with OLTS and LSPM instruments before setting a reference and then using the instrument to make measurements. It is equally important to inspect and clean, if necessary, all the fiber connectors in the patch panel or in the cassette before testing.

What is often overlooked are the connectors on the test instruments themselves. Feedback from our service centers indicates that a very high percentage of instruments sent in for repair were only suffering from dirty fiber optic connectors.

Inspecting and cleaning of instrument connectors can be carried out in the field, you just need to have the right equipment. That equipment is the very same equipment that is used to inspect and clean TRCs and connectors in patch panels.

You need the following:

The inspection and cleaning process is straightforward, but care needs to be taken so as not to damage the fiber ferrules of the CertiFiber Pro® Output Ports, which are the only contact ports in the module. The Power Meter Input Port of the CertiFiber Pro® is a non-contact port, so there is no ferrule cleaning required, but the port adapter does need to be checked for dust and dirt.

To inspect the output ports of the CertiFiber Pro® Module, do not disassemble the adapter to expose the ferrule. If you do so, you may accidently damage the ferrule, even break it, leading to an expensive repair. The preferred method is to inspect the output port using a 2.5mm bulkhead tip fitted to the FI-1000 FiberInspector™ camera.

Lay the instrument on its back with the port cover out to one side; carefully insert the camera tip into the port with the camera on its side. Please refer to the picture below on how to orientate the camera correctly to insert it into the output ports.

Manipulate the camera position carefully to get the image centered and use the camera focus control to obtain a clear image. You can save the captured image for reference.

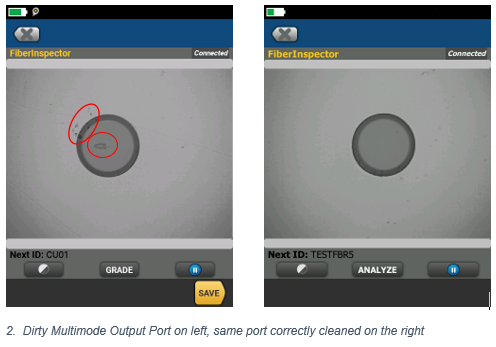

Below, Figure 2., is a typically dirty Multimode Output Port from a CertiFiber Pro®, and that same port cleaned, notice the dirt mark near the center of the ferrule and the dirt near the glue line, both circled. Fluke Networks uses special ferrules in its CertiFiber Pro®, so the core area will appear a lot larger than what is usual when looking at a normal connector.

To clean a dirty port, the simplest method is to use Fluke Networks 2.5mm Quick Clean™ product. This is a click style cleaner and is ideal for cleaning contamination off the ferrule that has not been “baked” on. If the contamination is heavy, you should perform a wet clean first using a 2.5mm swab dampened with Fluke Networks Cleaning Solvent, then follow with a dry 2.5mm swab to dry up any residual moisture. A 2.5mm Quick Clean™ can also be used to finish off the cleaning process. Remember, dirt will block the light coming from the port and will cause poor measurement results. Really dirty output ports will generate power level warnings during the Set Reference procedure when using the CertiFiber Pro®.

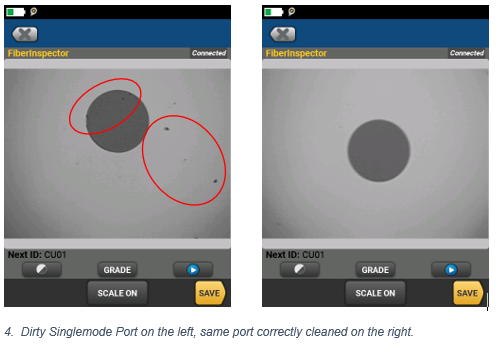

The process for inspecting and cleaning the Singlemode Output Port is the same. Carefully lay the instrument on its back, remove the protective cover from the port and move it to one side. The camera is carefully inserted into the SM port, then center and focus the image on the screen. Carefully look for scratches, defects and dirt that may prevent the instrument from working correctly. Below, Figure 4., is a SM port that has dirt issues, circled in red. To the right is the same port, correctly cleaned.

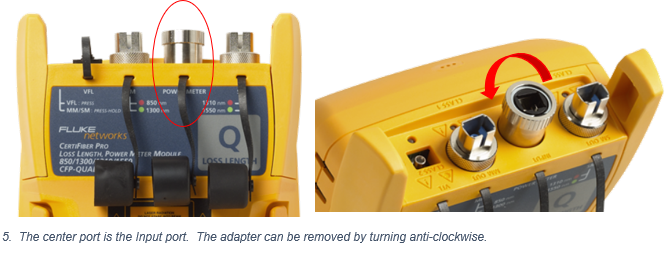

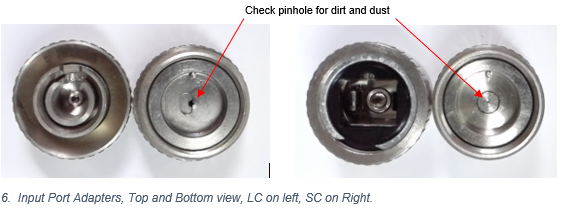

As mentioned earlier, the Power Meter Input Port, circled below left, is a non-contact port; there is no ferrule to clean. The port adapter should be carefully removed and the detector surface should be inspected for contamination. Carefully look at the adapter, there will be a small pinhole at the bottom, check that there is no dust or contamination in the hole. Check that there is no contamination inside the adapter where the TRC is inserted. If you are satisfied that everything is clean, screw the port adapter back on, making sure you observe the alignment marks.

You cannot hope to achieve good measurement results if your fiber connectors are dirty, same goes for the ports on your test instruments. You should inspect your instrument ports as part of the same process that involves inspecting and cleaning your Test Reference Cords, before attempting to set a reference and carry out measurements.